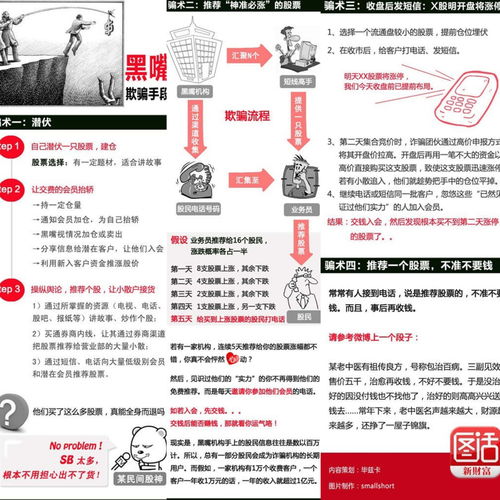

世讯买股票骗局

骗术一:潜伏

第1步:自己潜伏一只股票

黑嘴机构们首先会自己先偷偷潜伏一只股票,这类股票往往盘子适中,有一定题材,比较适合讲故事。

第2步:让交费的会员抬轿

黑嘴机构在自己有一定持仓量之后,就会开始通知高级会员建仓,顺便给让他们给自己抬抬轿。

这些会员买入的时候,黑嘴们会根据情况适当的加仓或者卖出一定的股票,使得股价走出比较漂亮的图开,又不至于被迅速推高。

在这个过程的后期,他们会把信息分享给一部分潜在的客户,一来是分一部分利润给他们,好让他们尽快交钱入会,补充因不断亏损而不断流失的会员;二来,可以继续利用他们的资金推涨一下股价。

第3步:操作舆论,推荐股票,让小散户接货

这个时候,黑嘴机构们,会在自己掌握的所有资源(在电视、电话、报纸、博客、股吧等等地方)讲故事、讲题材,炒作支股票。甚至会买通券商的内线,让其通过券商的渠道把股票推荐给营业部的大量小散。同时通过短信、电话向大量的低级别会员和潜在会员推荐股票。

这个过程一般会比较长,除极个别情况外,股价都会稳定上涨,也有机构会暴力狂拉涨停板吸引注意力。会在这个过程中,黑嘴们慢慢清空自己的仓位→然后,通知自己的会员清空→然后,通过有意向加入他们会员的人清空。

这个中间会有一个问题:他们买了这么多股票,真的能够全身而退吗?答案是:No problem!某民间股神曾说过,SB太多了,根本不要担心出不了货!

骗术二:为什么骗子推荐的股票这么准?

小编曾不止一次的想:最早想到第二种骗局的,一定是数据天才。

骗局的要点:

1、首先,骗子机构确实汇聚了几个短线高手,他们在追逐热点,选择短线个股上面确实有一手。这几个高手,每天会提前给每个业务员一组股票。

2、骗子手里得有通过各种方法收集到的,大量股民的电话号码,这里我们假设是16个。

3、骗子把股票推荐给这16个股民。假如涨跌的概率各占一半的话,就会有8个人的股票出现上涨。第二天,他们再给头天上涨的这8人打电话推荐一只股票。假如涨跌的概率各占一半的话,还有4个人;第三天,他们再给买到上涨的4人打电话荐股,第四天,他们再给这上涨的2人打电话荐股,第五天,他们再给买到上涨的股票的那一个人打电话。

如果有一家机构,连续5天给你的股票都是上涨的。而且如果这5只个股的连续涨幅都不错的话。那么,你有可能再也得不到他们的好股票了。取而代之的是,每天邀请您参加他们会员的电话,毕竟您是见过他们“实力”的。

可是,赚到钱只能说明是你的“财运”好,跟这个机构其实没有太大的关系。所以,往往会出现很多,不交钱的时候天天推荐的股票都很准,一入会,马上就不行了的情况。当然了,还有一些财运极佳的“受害者”们能够长期从这些诈骗机构推荐的个股中赚钱。这里为了方便,我们的举例只用了16这个数字。可是诈骗机构手上的股民信息往往是数以百万计。所以,总有一部分股民会成为诈骗机构的长期用户。而假如,一家机构有1万个收费客户,一个客户一年收1万元的话,一年的收入就超过1亿元。

骗术三:收盘后的短信:XX股明天开盘会涨停

第三个案例跟操纵市场有一定的相似性,就是放出小道消息吸引投资者跟盘。这种骗术的要点主要有以下几点:

诈骗团伙会首先选择一个流通盘较小的股票,然后提前进行仓位埋伏。

第二,在收市的之后时候,给手里的客户打电话、发短信。内容大致是:“明天这只股票涨停,我们今天收盘前已经提前布局。”

因为这是一小盘股,不需要很大的资金量就能将它炒高。第二天,在集合竞价,诈骗团伙通过高价申报的方式,将其开盘价拉高……等开盘之后,用一笔不大的资金以高价直接购买这支股票,很容易导致这支股票迅速涨停。如果有小散追入,他们就趁势把手中的仓位平掉。当然,这是第一步。

第二步,就是忽悠头一天接到电话的人,“已然见证过他们的实力”的人加入会员。当然,一量你交了费,你会发现,你永远买不到这种第二天开盘能涨停的股票。

骗术四:推荐一个股票,不准不要钱

经常有人接到电话,说是推荐股票的,不准不要钱。而且,事后再收钱。

关于,这个骗术……小编想起一个段子:

某老中医有祖传良方,号称包治百病。三副见效,售价五千,治愈再收钱,不好不要钱。于是没治好的因没付钱也不找他了,治好的则高高兴兴送钱去……常年下来,老中医名声越来越大,财源越来越多,还挣了一屋子锦旗。所以,这种不准不要钱的荐股,自己去体会吧!

最后,要说明一下,这几种骗局不是那么好学的。尤其是第三种骗术,经常有庄家不小心把自己玩儿死的。所以,你非要说这些骗局是我瞎说的,根本不可能有人上当。那我只能说,不要太高估股民的智商了。要不然那些在路边摆个小碗的乞丐也不会是高收入群体了。

世讯工业天津有限公司

1998 and documents, works at the Tianjin Tianlong Paper Co., Ltd., engaged in electrical instrumentation maintenance work.

Main duties: the entry of new companies this year to participate in a project to install commissioning work, a lot of learning during the foreign advanced electrical meters. The electrical, pneumatic and hydraulic equipment, such as a deep understanding. Master at work in a lot of high and low voltage electrical equipment maintenance and repair experience, during the workshop responsible for the factory boiler (35 tons furnace) and the drainage treatment plant to the electrical instrumentation of the day-to-day maintenance and repair work.

2002 2005, Kim worked for the Tianjin Science and Technology Paper Co., Ltd., posts: electrical technician.

Main duties: responsible for the DCS, QCS system and the electrical instrumentation routine maintenance and repair. 2004, head of the instrument, and participated in the factory on 35 KV substations and low-voltage power distribution room regularly sweeping overhaul of work. In the course of Siemens PLC accepted the Frequency Control and routine maintenance of learning. I have made in 2004 in Tianjin Verification awarded Members of the verification certificate, the same year took part in the Tianjin Health Bureau of radioactivity in the training of staff and obtain radioactive engaged in the work of the certificate.

Since 2005, worked for ITT (Tianjin World's Industrial Co., Ltd.), positions: Maintenance Technician.

Main duties: responsible for the whole factory production lines. Quality inspection departments and machining equipment and routine maintenance, repair and technological transformation, the formulation of each piece of equipment PM security work plan and analysis table listing locking system, and to conclude ME engineers reported regularly to the operation of the equipment. June 2007 to participate in the Company RMU Pelikon new projects and the entire process, and is responsible for electrical projects Pelikon part of the design, installation and debugging the same year the project successful trial operation. During the study in the use of grinders, milling machines, and other machining equipment. In ITT I participated in the 5 S and TPM full equipment maintenance and management of training and quality certification system of training, to enhance production efficiency, stability, product quality, reduce costs, and equipment of the highest efficiency in the use of a function to lay a good foundation.

I engaged in electrical work for nine years, automation, instrumentation and high and low voltage electrical equipment, a good foundation, independent of the PLC frequency servo systems, such as human-computer interface for maintenance and PLC programming, with heavy industry, electronics manufacturing, and other electrical equipment The daily maintenance and overhaul and has accumulated rich experience, to understand and simple to use CAD plans to skilled use of commonly used office software. Familiar with the work of foreign enterprises and management methods.

I am a serious and responsible work, be able to unite innovation, and be good at listening to suggestions, firmly believe that the team strength, can be very good in the handling of the various relationships in the hope of your company and the common development and common progress.

0 留言